ChemcAI

Solutions

Data Driven | Industrial Engineering | Process Optimization

Services

Any Industrial Problems?

Opt for Data Driven CHEMCAI Services

Experienced Team

Experience in Process control, Data Science and Solution design can create a customized solution for your problems.

Plant Understanding

Team has understanding of Chemical Engineering, Industrial Engineering, DCS, PLC and other control systems.

AI and Chemical Expertise

Deep knowledge of chemical concepts and Various AI Tools.

Products

Ready Mix Concrete Industry

Conkro AI is an innovative artificial intelligence-driven simulator designed to optimize the quality of concrete production. Conkro AI ensures consistent and high-quality concrete output 24/7, mitigating the impact of variables such as fluctuating raw material quality,climatic condition,geographial differences and human errors. By utilizing data-driven insights and real-time analysis, Conkro AI recommends optimized ready-mix recipes, enabling precise control over the concrete production process, empowering stakeholders to make informed decisions and take corrective actions as needed.

Chemical Research & Development

INNOBOT is transforming R&D with AI-driven solutions that significantly reduce time and costs. Our platform features an Artificial Intelligence Simulation Based Model,Workflow Automation, User-Friendly Interface, and Customizable Dashboards, enabling faster and more accurate results. R&D sector can utilize INNOBOT to accelerate their product development cycle. To simulate complex chemical reactions and predict optimal conditions. Analyze vast amounts of research data to identify patterns and trends. Access real-time insights and customized dashboards for informed decision-making. As a result, the company significantly reduced their product launch timeline from several months to just a few weeks while maintaining high-quality standards.

Process Monitoring

In the realm of Chemical Engineering, our team showcases a profound understanding of computer vision applications such as plant equipment monitoring, Material Quality classification, Liquid Level Detection and Particle Size Analysis. Leveraging our in-depth knowledge and hands-on experience, we demonstrate proficiency in creating sophisticated solutions that harness state-of-the-art visual technologies. These solutions are designed to precisely identify levels, monitor the health of industrial equipment, and processes. By doing so, we deliver invaluable insights and facilitate process optimization across diverse industries.

Virtual Sensor

Our developed digital sensor for plant parameters utilizes machine learning and mathematical modeling to estimate variables without physical instrumentation. It enables real-time monitoring, optimizing operations, enhancing productivity, and reducing costs. Versatile and accurate, this invaluable tool empowers operators across various industries to make informed decisions and ensure optimal process efficiency

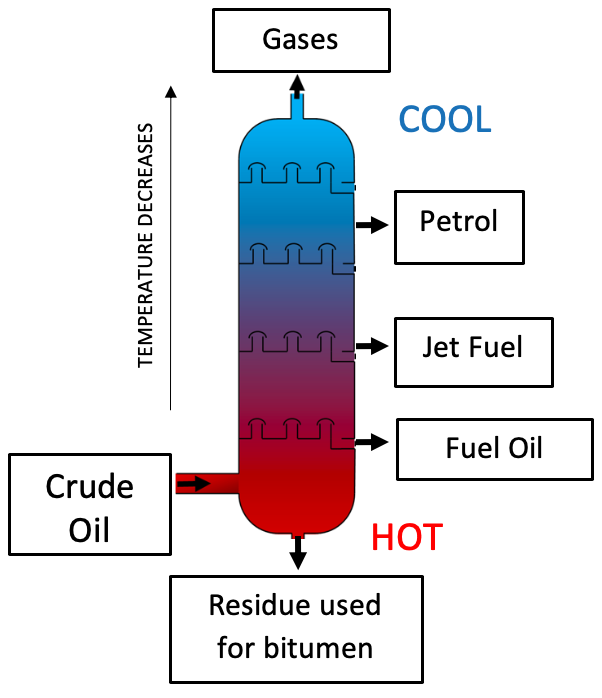

Distillation

Artificial intelligence (AI) is transforming distillation column operations by utilizing real-time data analysis and predictive modeling to recommend optimal parameters. These AI systems analyze feed composition, temperature, pressure, and other factors to continuously optimize column performance, resulting in improved efficiency, reduced energy consumption, and enhanced product quality. By automating routine adjustments and predicting maintenance needs, AI reduces operator workload, enhances safety, and lowers operational costs. Real-world implementations have demonstrated significant energy savings and improved product purity, highlighting the profound impact of AI in enhancing the efficiency and sustainability of distillation processes.